1 / 3

1 / 3Vision based material handling with an igus cobot

Hardware Price:

DOF

6

Precision

+- 1

mm

Max. reach

660

mm

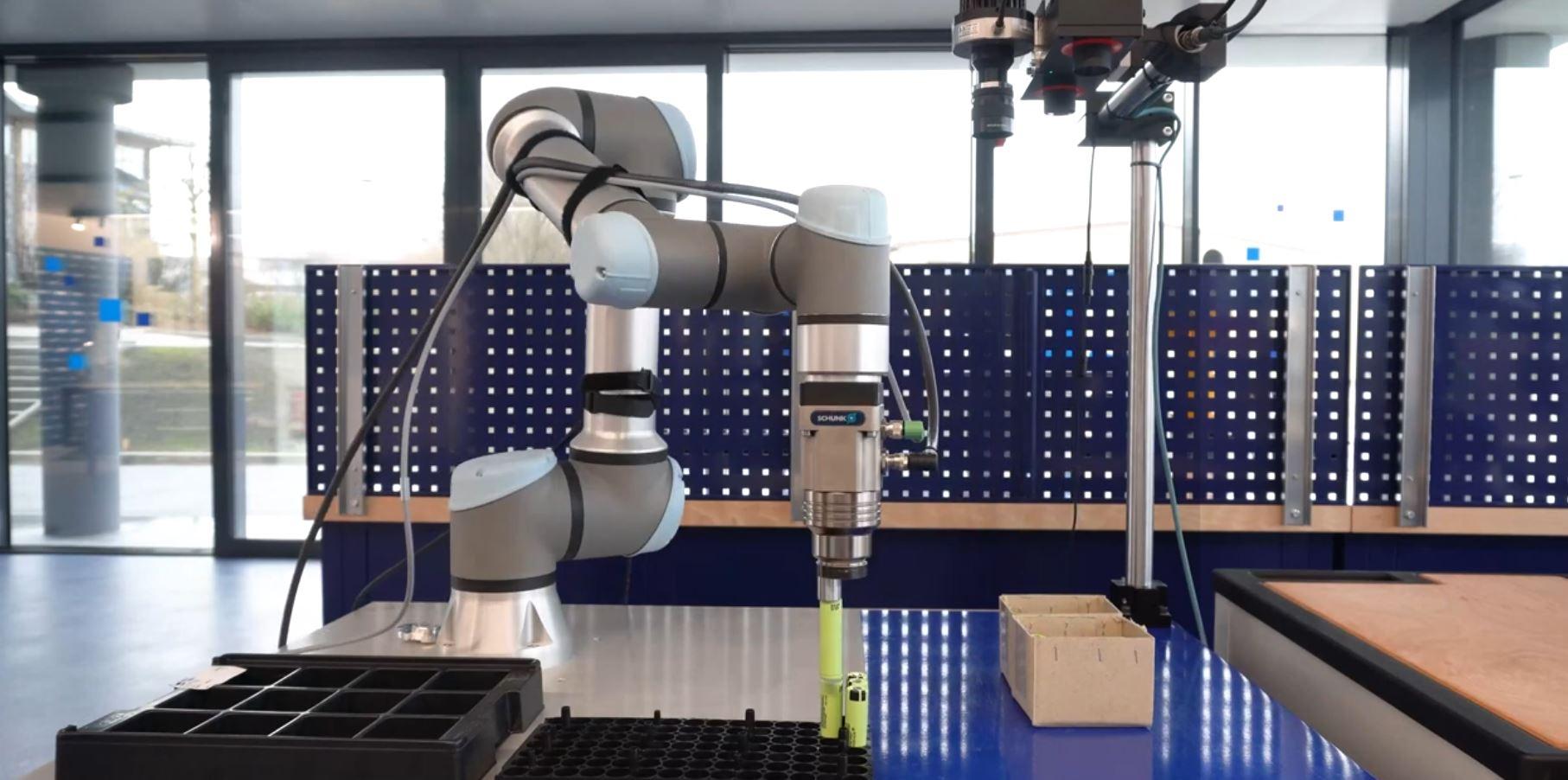

Enhancing Pick-and-Place Tasks with igus ReBeL and ifm 2D Camera

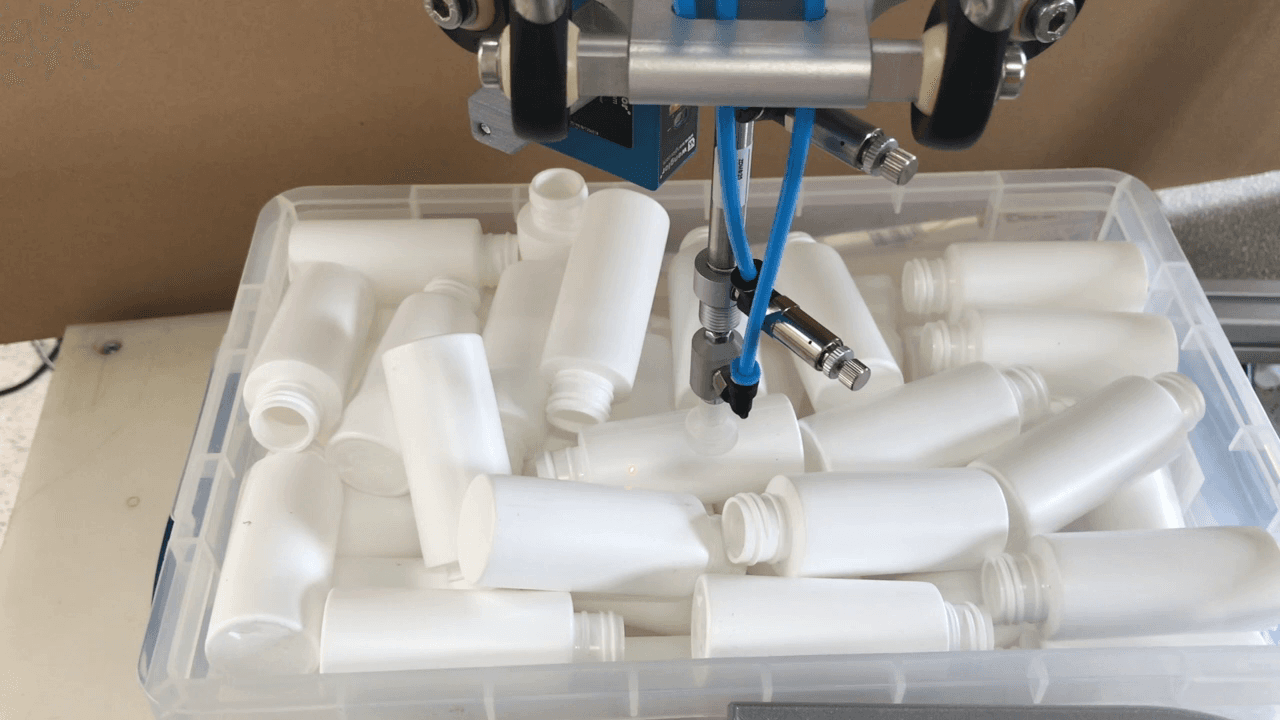

In automation, seamless compatibility between robots and camera systems is essential for precision and efficiency. This example demonstrates the collaboration between the igus Cobot ReBeL and an ifm 2D camera, enabling accurate detection and handling of components in bulk materials or "grip in the box" scenarios. The camera transmits the coordinates of the pre-taught components directly to the robot, ensuring smooth and precise operations for pick-and-place tasks.

What is the Application?

The solution automates pick-and-place processes for bulk materials, guiding the ReBeL robot with real-time data from the camera to identify and handle assorted items accurately.

What are the Advantages of the Solution?

High Precision: Camera-guided coordination ensures accurate picking even with disordered bulk materials.

Versatile Use: Suitable for various industries, from logistics to manufacturing.

Guaranteed Compatibility: igus is pre-integrated into the camera software.

What are the Advantages of the Robot?

The igus ReBeL cobot enhances the productivity of pick-and-place tasks:

Ease of Integration: Plug-and-play compatibility simplifies setup.

Lightweight Design: Allows for easy mobility and diverse applications.

Cost-Efficiency: Offers affordability without compromising on performance.

Flexible and Precise Automation with igus ReBeL

The synergy of the ReBeL cobot and ifm 2D camera provides an intuitive, efficient solution for automated pick-and-place tasks. This integration optimizes workflows by combining precise material handling with simple integration and reliable operation, empowering businesses across industries to enhance their productivity and cost-effectiveness.

4 Components