Three things you should consider when automating pick & place

Whether in packaging, assembly, quality control, or logistics – pick & place processes are among the most common and repetitive tasks in industrial manufacturing. This is exactly where there is enormous potential for automation. With the cost-effective and easily integrable robotics solutions from RBTX and igus, companies of all sizes can increase productivity while conserving resources.

On this page, you’ll learn what matters when automating pick & place, the benefits it offers, and how to step-by-step reach your optimal solution.

Three things you should consider when automating pick & place

Selecting the right gripper is essential

Not every gripper is suitable for every product. The decisive factors are the shape, weight, material and sensitivity of the object to be moved. At RBTX you will find a large selection of vacuum, parallel and adaptive grippers - including advice on selection.

Review cycle time and process needs carefully

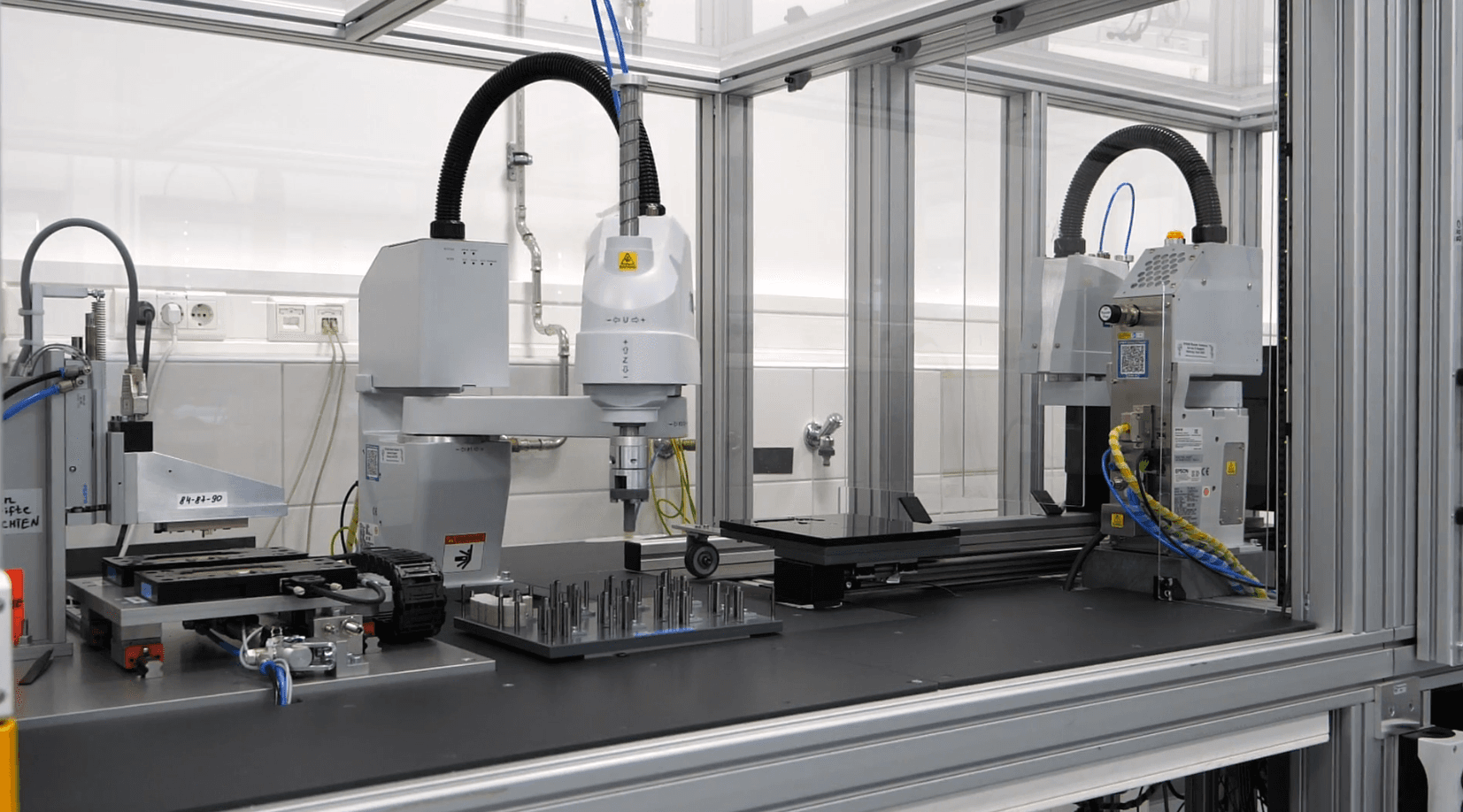

How fast does the robot have to work? How many parts per minute should be moved? A realistic assessment of the cycle time helps in selecting the right type of robot - whether delta, SCARA or articulated arm robots.

Know your system’s positioning accuracy and repeatability

For precise pick & place tasks, it is not only accuracy that is decisive, but above all repeatability. igus robots offer repeatability of up to ±0.5 mm - ideal for many industrial applications.

How to get started with Pick & Place automation

Discover the key steps to begin automating Pick & Place tasks—from choosing the right components to setting up your system

Define the use case

What parts need to be moved? How large, heavy, and sensitive are they?

Find the right solution

At RBTX.com, you’ll find verified complete solutions – including robot, gripper, controller, and accessories.

Use the free consultation service

Our experts help you choose and answer all technical questions

Get it tested

Use the RBTX testing service – we’ll test your application in advance with real robots

Integration & training

igus supports you during commissioning and offers hands-on training for your team.

RBTXpert Conclusion

Many people initially underestimate how important it is to feed and remove the parts cleanly. You can have the best robot and the perfect gripper - if the parts are askew, slip or are not ready in time, none of this will help you. Plan the infeed just as carefully as the robot itself. Whether it's a chute, conveyor belt or magazine - it has to be stable, repeatable and customised to the process. And also think about the outfeed: Where do the parts end up? How are they processed further? If this runs smoothly, you have real automation - not just a robot standing around.

Advantages of automation in Pick & Place processes

Automation makes Pick & Place tasks faster, more accurate, and less tiring.

Consistent quality

Robots operate with precision and without fatigue—regardless of shift length or personnel changes

Higher speed

Automated systems can achieve significantly higher cycle rates than manual processes

Cost savings

Lower scrap rates, reduced labor costs, and scheduled maintenance contribute to long-term operational savings

Scalability

Robotic cells can be flexibly adapted to new products or changing production volumes

Get started, find your solution now!

Elite Robots

Fairino

Polytechnic of Milan

igus

Lucifer Chocolate

Fairino

Fairino

Fairino

FAQ

Frequently asked questions