3 things to consider when automating 3D printing

3D printing has evolved from a prototyping technology to a fully-fledged production process. However, with increasing quantities and rising quality requirements, it is becoming clear that manual post-processing, material handling and machine operation are time-consuming and prone to errors. The solution? Automation. It makes 3D printing scalable, efficient and economical – even for series production.

With the modular and cost-effective solutions on the RBTX marketplace from igus, companies can automate their 3D printing processes – from material feeding and removal to post-processing.

3 things to consider when automating 3D printing

Identify process steps that can be automated. Typical automation options in 3D printing include

Material handling: Automatic feeding of filament, powder or resin. Part removal: Robotic arms remove finished parts from the printer. Post-processing: Cleaning, support removal, surface treatment. A process analysis helps to identify the greatest levers for efficiency and quality.

Ensure compatibility with printing systems

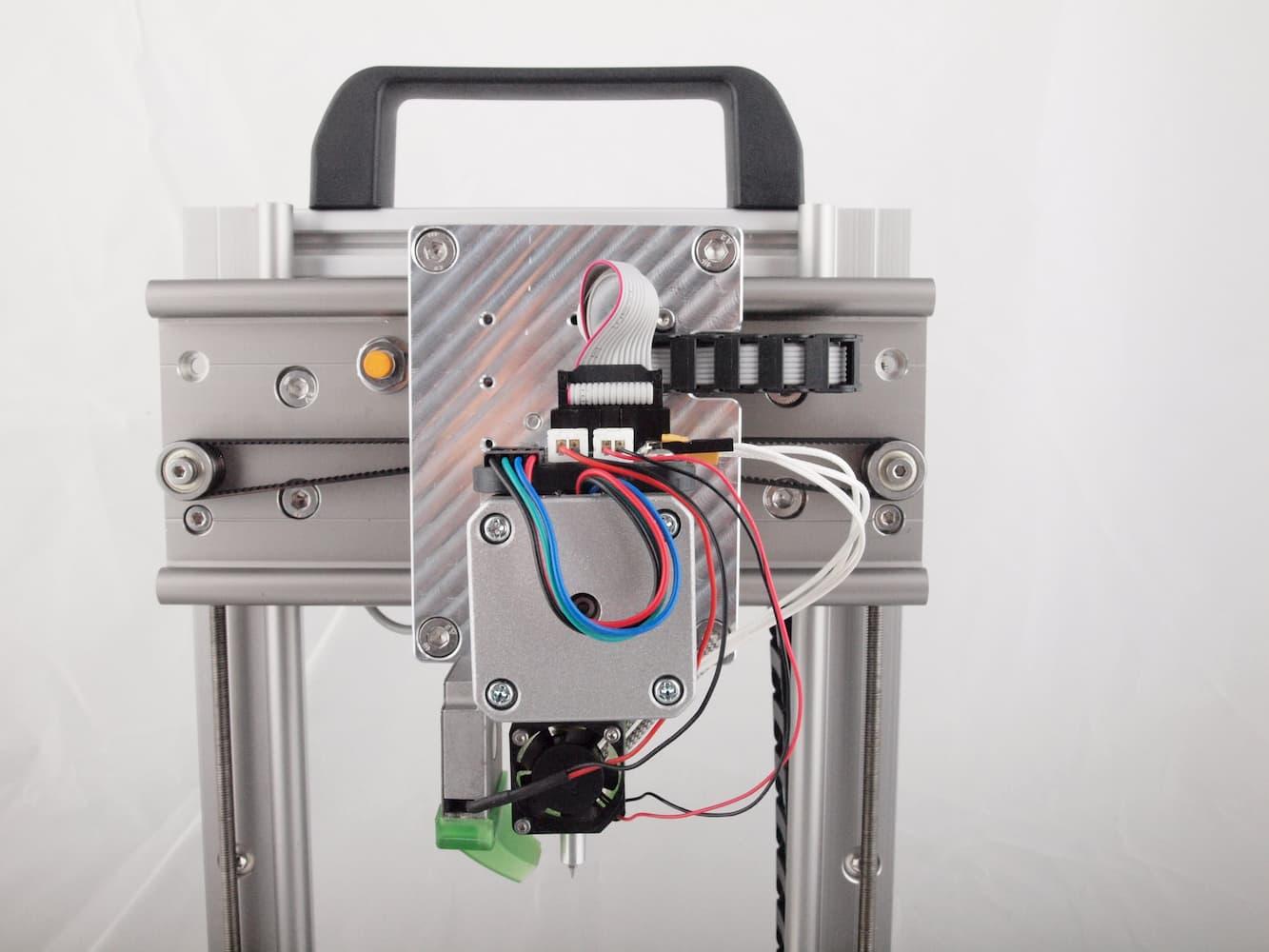

Automation solutions must be mechanically and software-compatible with your printers. Look for open interfaces, standardised controls and flexible gripper solutions that can be adapted to different printer models and component geometries.

Plan for scalability and repeatability

Automation is particularly worthwhile for series production or continuous operation. Systems should therefore be modularly expandable and precisely controllable – e.g. through linear axes, robot arms or AI-supported image processing for component recognition.

How to get started with your automation solution in 3D printing

Discover the key steps to begin automating 3D printing tasks – from selecting the right components to setting up a scalable, smart system

Define the application

Which tasks should be automated? Is it material feeding, component removal, cleaning, or sorting?

Select suitable components On the RBTX marketplace, you will find:

Robotic arms & grippers, Linear units & conveyor technology, Controls & sensors, Complete solutions for automated cells

Use tests & consulting

Have your application tested with the RBTX “test before invest” service or take advantage of the free consulting service – practical, individualized, and non-binding.

Integration & commissioning

Many systems are plug-and-play and can be integrated into existing 3D printing processes with minimal effort. igus offers support, CAD data, service life calculators, and online configurators.

RBTXpert Conclusion

In 3D printing, consistent quality matters more than speed. Use automation for quality assurance—like AI-based image recognition or sensors for process monitoring—to detect errors early and reduce waste. Especially in series production, repeatability is key, achievable only through standardized, automated workflows. The RBTX marketplace offers modular components—from robot arms to conveyors and smart cameras—ideal for scalable, reliable automation.

Advantages of automation from 3D printing

Automation in 3D printing offers streamlining workflows, improving consistency, and enabling scalable production

Higher productivity

Automated systems operate around the clock – without breaks or personnel commitments.

Consistent quality

Repeatable processes reduce errors and waste.

Cost savings

Less manual work, shorter throughput times and optimised use of materials.

Scalability

Series production becomes economical and predictable.

Safety & ergonomics

Automation reduces physically demanding activities and minimises risks

Get started, find your solution now!

Fraunhofer

Fablab Karlsruhe

MEGATRON

Purpose AM Systems

Protoworx UG

DUS Architects, Actual

igus® GmbH

Protoworx UG

FAQ

Frequently asked questions about automation in 3D printing